Call us 0597-3217790

E-mall fujiankailong@gmail.com

Longyan Kailong Mining Equipment Co., Ltd.

Common knowledge of mid-deep hole blasting interval

In order to reduce the blasting cost, interstitial filling is often used.

There are three ways to finish the interval:

Water interval filling, rock powder interval filling, gas interval filling

The water interval filling is only easy to achieve at the bottom interval, and the operation is cumbersome, so most of surface mines are not selected this way.

Although the rock powder interval filling saves some explosives, the blasting effect is relatively poor, and it is easy to produce large blocks in the interval position.

Reasonable gas spacing can achieve non-coupling filling and rise the center height of the explosives. Its main advantages include the following:

I:keeping the explosion effect, the gas interval part does not contain explosives, which directly reduces the explosion cost.

II:It reduces the radius of the over-smash zone, expands the fracture zone of the rock, increases the stress wave effect and the action time of the explosive on the rock, which is conducive to improving the energy utilization rate of explosives, improving the crushing effect, and reducing the rate of large blocks. It provides favorable conditions for improving the loading efficiency after blasting.

III:Due to the action of the air column, the blasting vibration can be reduced, and the bottom gas interval is the most obvious.

IV: Gas bag can be placed anywhere in the hole. For the holes with large caves or cracks, they can be blocked by gas bags, which has certain benefits for filling and blasting effects.

V:Underground VCR mining, can use the gas bags to block and interval, the gas bag is convenient, accurate, safety. So gas bag spacing is adopted on the interval filling now ,especially on the middle and deep hole blasting.

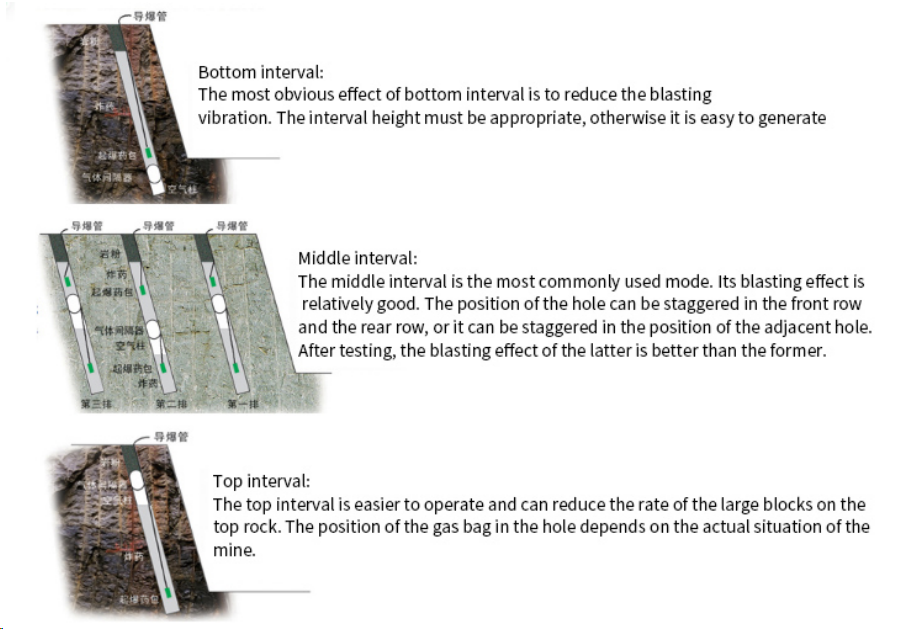

According to the position of the gas bag in the hole, there are three modes to space:

Charge amount:

90 holes loaded with 6 kilograms of explosives per meter

115 holes loaded with 10 kilograms of explosives per meter

140 holes loaded with 15 kilograms of explosives per meter

165 holes are loaded with 20 kilograms of explosive per meter.

Spacers can only be used for blast holes that are over 10 meters deep. Typically, for open-air medium deep holes that are 15 to 20 meters deep, one should be used for each hole, with a spacing height of 1.5 to 2 meters, which means a less explosive charge of 1.5 to 2 meters. Do not exceed 2 meters, this is more ideal, the post explosion effect is good, and the block size is even.

The gas spacer comes with a compressed gas cylinder, which is convenient to use. It is 60 centimeters long and can be adjusted in height by a rope. It can be spaced at any distance within the borehole, usually in the middle of the borehole. The gas is released from the borehole mouth to the desired interval position in about 30 seconds, which is sufficient time and does not block the borehole.

We have various factories and products, experienced technicians and sales team, professional quality assurance and after-sales team to help your business start and succeed.

* We promise that we will never disclose your privacy.