Call us 0597-3217790

E-mall fujiankailong@gmail.com

Longyan Kailong Mining Equipment Co., Ltd.

blast bags , as used in both open cut and underground blasting, are a self-inflating bag that, when activated and lowered down or placed up a blast hole, will seal off the blast hole, giving you an effective deck for loading explosives and/or stemming.

* The KUANGBAO Gas Bag is a self inflating borehole plug that is used to block or seal a hole at any depth. They are made for 3" to 16" diameter holes.

* There is no need for an air compressor, for the bags self inflate chemically. There is no leakage because the Gas Bag is sealed during manufacture.

* There is no heat produced during inflation and the ingredients are not carcinogenic.

* Substantial savings of up to 35% in explosives costs can be made by using the Gas Bag for air column blasting techniques.

How To Use The Gas Bag

* Gas Bags come pre-folded for ease of handling. They are held together by tape or rubber bands. Do not remove these because they allow the Gas Bag to inflate properly.

*Attach a cord to the tag at the top so that the Bag can be lowered to the correct depth in the hole.

* In the case of the vinegar Gas Bag, squeeze the colored liquid container and pop it. This releases the vinegar onto the sodium bicarbonate. Make sure all the vinegar has drained onto the bicarb pouch then lower in the hole. You have about 40 seconds to get the Bag in place before inflation starts. When the Bag is tight in the hole, remove the cord with a sharp tug.

Uses For The Stemlock Gas Bag

* Air deck production blasting for savings of up to 35% of your explosives consumption.

* Drop a Gas Bag on top of small amounts of water and use ANFO instead of cartridge or bulk emulsion.

* Pre-splitting with large diameter holes for slope stability on coal surface mine high walls.

* Reduce AIF noise and possible

* Pit limit stabilization to increase minable ore in limited areas.

* Block off holes through old workings or natural cavities and the bottoms of holes in VCR work.

* Seal off exploration holes at a reasonable depth with concrete poured on top of the Gas Bag.

* Limit throw from opening holes on narrow benches to contain the muck pile.

* Temporary seals for drill holes between mine levels.

Production Blasting With Less Explosives

* Save 15% to 35% of the total explosive load and still have excellent dig-ability. It's possible to reduce vibration and noise in addition to cost savings.

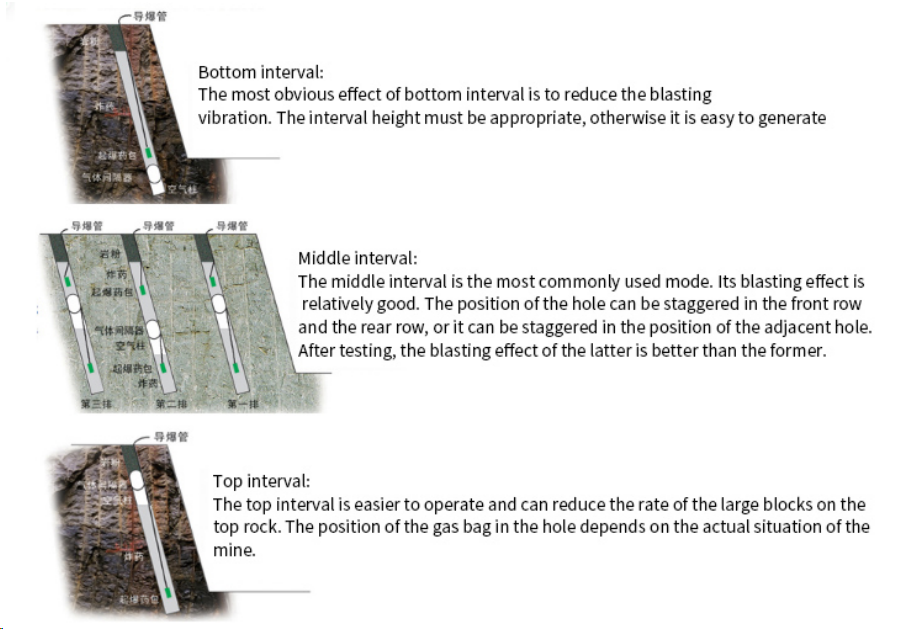

* Mid-column air decks normally produce the best results especially for casting but top air decks will save you money and are easier to do.

* Start your program by reducing the explosive by 15% of the total length of the hole while leaving the stemming height the same. Check blast results and continue to decrease explosives by 2-1/2% at a time until you see unsatisfactory results.

* It may be possible to reduce the stemming height for better top breakage also without stemming ejection.

Reduce Expensive Explosives / Substitute ANFO for Emulsion Blends

* If your holes have only a few feet of water, try dropping a Gas Bag on the water to seal off the hole. Add a little stemming and use ANFO instead of waterproof explosives. Generally you can use this system up to 8 times the borehole diameter of water.

* If you have more water, put in a toe charge which will make the water rise, then put the Gas Bag on top of the water and use ANFO for the rest of the charge. The toe charge should be about 30% to 40% of the total charge.

Using Gas Bags With A Cavity

* Block a void or cavity that the drilled hole has penetrated.

* Plug holes in Vertical Crater Retreat mine methods.

* Plug exploration holes.

Presplitting

Presplitting Rules Of Thumb

* Hole spacing should be 15 to 24 times the borehole diameter in inches depending on the local geology. A good example for many coal highwalls is 18 foot spacing for a 10-5/8" hole.

* If the hole is over 50 feet deep, two or more charges should be used for better explosive distribution. Usually about 60% of the total charge should be in the bottom.

* Charge weights should range between 3% to 10% of the total charge in a normal production hole.

* Holes should be stemmed for best results and for noise reduction.

We have various factories and products, experienced technicians and sales team, professional quality assurance and after-sales team to help your business start and succeed.

* We promise that we will never disclose your privacy.