Call us 0597-3217790

E-mall fujiankailong@gmail.com

Longyan Kailong Mining Equipment Co., Ltd.

In the realm of mining and tunneling, mid-deep hole blasting techniques are essential for the efficient excavation of rock and soil. These methods rely heavily on the use of explosives, but the precise deployment of these explosives is equally crucial. One key component in achieving optimal blasting results is the utilization of gas bags, gas spacers, and air spacers.

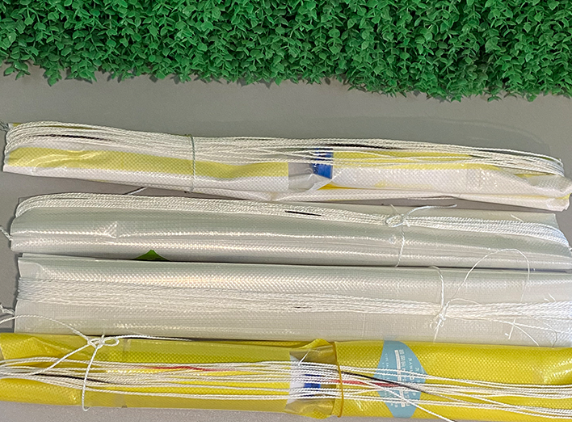

Gas bags, also known as air cushions, are inflatable devices that are placed within the blast hole to separate the explosives from the surrounding rock. They serve to contain the explosive gases generated during detonation, minimizing the risk of damage to the surrounding rock mass. Gas bags are made from durable materials that can withstand the extreme pressures and temperatures generated during blasting.

Gas spacers, on the other hand, are solid devices that occupy a certain volume within the blast hole, without being inflated. They are used to create a buffer zone between the explosives and the rock face, ensuring that the explosive energy is distributed evenly and efficiently. Gas spacers can be made from various materials, depending on the specific requirements of the blasting operation.

Air spacers, similar to gas spacers, occupy space within the blast hole but do not contain any gases. They are often used in combination with gas bags and gas spacers to achieve the desired blasting pattern. Air spacers help to distribute the explosives more uniformly, minimizing the chances of under- or over-breaking.

The combination of gas bags, gas spacers, and air spacers allows for more control and precision in mid-deep hole blasting operations. By precisely positioning these devices within the blast hole, engineers can ensure that the explosive energy is directed towards the desired target, while minimizing collateral damage to the surrounding rock mass. This not only improves the efficiency of the blasting operation but also enhances the safety of the workers involved.